Time:2023-08-22 09:48:42 Share To

If you need our products,you can leave your contact informaction,our sales manager will send more information and quotation to you! Our email: [email protected], WeChat/whatsapp:+8613676922906.

1. Different shape and structure

(1) The jaw crusher has the advantages of simple structure, low investment cost, easy configuration, convenient maintenance and so on.

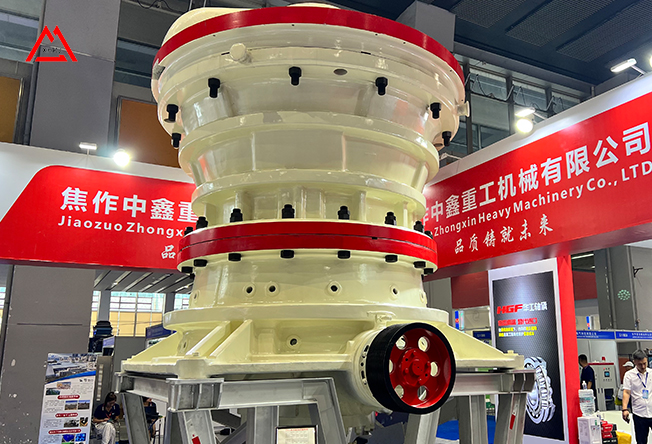

(2) The structure of the gyratory crusher is complex, the fuselage is high, the volume is large, the investment in equipment is large, a high workshop is required, the cost of infrastructure construction is high, and the heavy machine is not conducive to handling.

2. The applicable materials and scope are different

(1) The gyratory crusher can process ores of various hardnesses, but it is not suitable for crushing viscous ores. Because the gyratory crusher itself has a large volume and a larger output. It is widely used in mining, building materials, met urgy, chemical industry and other departments. It is mainly used for coarse crushing of materials with various hardness. The gyratory crusher is a typical coarse crushing equipment.

(2) The jaw crusher can process ore with high moisture and high viscosity, and it is not easy to block. Gener y, sm -scale concentrators and quarries *ly use jaw crushers as primary crushing.

3. Handle different particle sizes of incoming and outgoing materials

(1) The particle size of the feed material of the gyratory crusher is large, the particle size of the discharge material is sm , the particle size is uniform, and the content of needle-like particles is sm , gener y below 10%. The mine can enter the feeding port through the transportation tool, and there is no need to set up the feeding machine.

(2) The feed particle size of the jaw crusher is strictly required, and the size of the raw material be within the specified range. Feeders need to be set up. After the coarse crushing of the jaw crusher, the material particles are *ly flat, sharp or triangular needle-like particles, gener y more than 20%, and the product particle shape is not good.

4. The later maintenance cycle and the life of wearing parts are different

(1) The operating cost of the gyratory crusher is low, the maintenance interval is long, and it is difficult to replace the wearing parts. The gyratory crusher adopts the principle of laminated crushing between materials, and the crushing process is carried out continuously along the circular crushing cavity, which has a long service life than the wearing parts of the jaw crusher.

(2) The daily operation and maintenance of the jaw crusher are simple, and the wearing parts are easy to replace. The jaw crusher utilizes the extrusion action of the movable jaw plate and the static jaw plate to the crushing. The direct contact surface between the jaw plate and the material is large, the wear is fast, the life of the wearing parts is short, and the maintenance amount is large.

5. Different environmental effects

(1) The rotary breaker is fully enclosed with high sealing . There is less dust spillage during work, and the environmental protection effect is good.

(2) The jaw crusher is a semi-closed structure with low sealing . A large amount of dust gushes out during work, which will lead to unsatisfactory working conditions and serious environmental pollution.

The above are some basic comparisons about the rotary breaker and the jaw breaker. Both are suitable for coarse crushing of ore materials with high hardness. Which crushing effect is better, gyratory crusher or jaw crusher? This needs to be considered according to your own conditions. For example: your own requirements for the size of the stones, budget, site restrictions, infrastructure, environmental protection, etc. Knowing so much, I hope you can choose a crushing equipment that suits you.

Email: [email protected], Phone: 0086-371-67660555, Whatsapp/Wechat:+86-13676922906, Skype:[email protected]

Please feel free to give your inquiry in the form below. We will reply you in 24 hours